Topside Probing

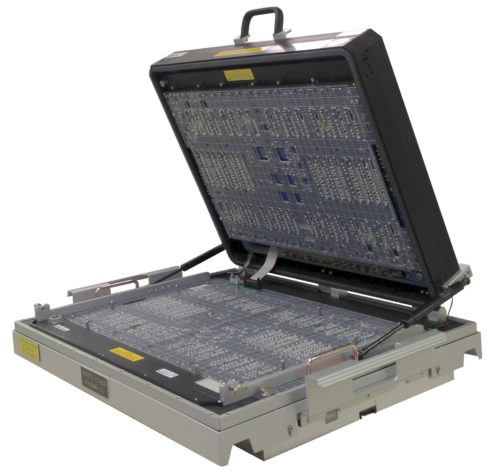

Circuit Check matches top side test targets to your specification and needs. The Signature Series pneumatic drive fixture is the industry standard for precision, accuracy and repeatability.

Today’s fifth generation Pneumatic drive supports as many as 8,000 test probes with centerline spacing to 25mil, and contacting test pads as small as 0.018″.

The Pinnacle Vacuum Box was designed exclusively to take advantage of our patented Auto Align technologies, while increasing the “Z” axis travel. This allowed the UUT’s support structure to better keep the UUT flat during its actuation cycle.

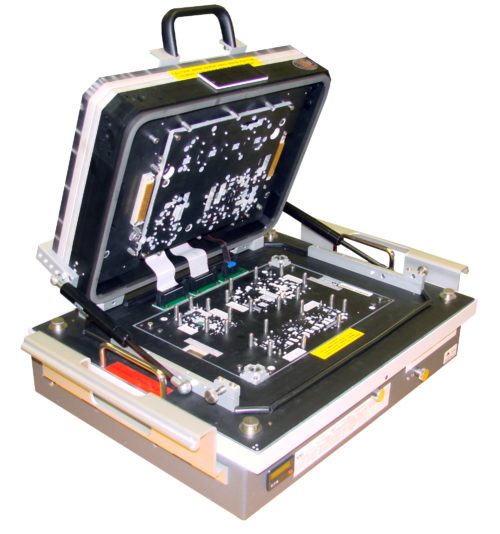

A patented vacuum alternative was introduced with the Performance Grade product line which incorporates attributes of the Pinnacle pneumatic drive fixture. This vacuum box uses Circuit Check’s Auto Align technology to accurately register the top side probes with the bottom side probes for repeatedly. Top side test pads down to 0.024″ can be contacted, while bottom side test pads of 0.022″ are supported.

The Auto Align design is protected by U.S. Patents 8,004,300 and 8,692,569. This is the same vacuum box that is now used with the Circuit Check Dual Check 2.0 Bi-Level fixtures.

In-Line board handlers add the automation required to meet the competitive manufacturing environment associated with high volume manufacturing. In-line fixturing for the following handlers:

- Circuit Check’s AFS5500

- Keysight 5i

- Teradyne TSh Multi-Site

- IPTE

- Pematech

These fixtures have many of the features found with standard fixtures:

- Bi-level (if in-line system allows)

- Dual Sided probing

- FrameScan/TestJet/VTEP

- LED sensing

- Marker probes

- Stripper plates

- Switch probes

You can trust Circuit Check’s automation experience for the right solution for your high volume production line.

Rugged Production Ready Testing…

In-circuit testing is the most important step in printed circuit board manufacturing. The test fixtures must be robust, reliable and delivered on time. We developed our vacuum box to be easily customizable to cover as large a range of boards without impacting turn around time.

Large boards on an extended kit can always be accommodated.

The Pinnacle vacuum box developed with over a half inch of vertical travel allows more accurate placement of board supports thus keeping the board planar. Our Quick Plate “Guided” probing technology and patented floating jumper plate using precision alignment features make

probing of 0.018ӯ topside targets and 0.016ӯ bottom side targets possible.

Heavy duty mechanical hold down gates:

- Adjustable rails

- Staticon / G10 plates which provide more accurate placement of board supports

- Ideal for low to medium probe counts

Mechanical drive units easily allowfor:

- Tall components on either side of the UUT

- Excessive heat generated during test

- Probing both sides of the UUT

- Manual side access units

In-Circuit Test (ICT) Fixtures & Turnkey Solution Products

ICT Programming Solutions

Actuation Methods

Vortex Series

Wireless

Tight Proximity Probing Technology

Drop-In

Multi-Stage

Topside Probing

Test Fixture Adapters

High Node Count

In-Line / Board Handler

FEA and Strain Gauge Testing

Expanding In-Circuit Capabilities